The war was not decided by tanks. It was not decided by planes. It was decided in a small room in a captured American supply depot where a German engineer held a single replacement part in his hands. He turned it over once, twice. Then he tried it on a damaged American vehicle. It fit. He tried it on another.

It fit. He tried it on a third. It fit perfectly. He stood there in silence. His colleague asked what was wrong. He did not answer because in that moment he understood something that no battle report could explain. The Americans had not built better machines. They had built a system.

And that system did not require perfection. It required only one thing, replaceability. This is the story of that realization and why once it arrived, the war was already over. November 12th, 1942, 6:47 a.m. The North African desert stretched cold and silent under a pale gray sky. Somewhere near Tbrook, inside a makeshift German repair facility, the smell of engine oil mixed with sand hung heavy in the still air.

A German tank sat motionless. Its transmission had failed 3 days earlier. 3 days. The crew waited. The mechanics waited. Everyone waited. Somewhere in Germany, a replacement part was being manufactured, hand fitted, precision ground to tolerances measured in fractions of a millimeter. It would take weeks to arrive, if it arrived at all.

70 mi away, an American jeep had suffered a similar failure. It was repaired in 4 hours. Not because American mechanics were faster, not because American parts were better, but because the replacement part was already there, sitting on a shelf, waiting, and it was identical to the one that had broken. This was not luck. This was not coincidence.

This was a decision made years before the first shot was fired. A decision that most German commanders would not understand until it was far too late. The Germans had built their war machine on a simple philosophy, [snorts] engineering excellence, precision, every component crafted to perform at maximum efficiency. Their tanks were marvel.

Their aircraft engines were works of art. Their optical systems were unmatched anywhere in the world. But there was a cost to this excellence. Every part was unique. Every repair required a specialist. Every failure became a crisis. The Americans understood something different. They understood that war was not a laboratory. War was chaos.

War was mud, sand, fire, and breakage. And in chaos, perfection was the enemy. What mattered was not how well a machine performed on its best day. What mattered was how quickly it could return to the fight on its worst day. The American factories did not build masterpieces. They built systems. Systems designed for one purpose, to keep moving no matter what.

And at the center of that system was a concept so simple that German engineers initially dismissed it. Interchangeable parts. Parts that required no hand fitting, no adjustment, no specialist. Parts that could be installed by any mechanic in any field under any conditions. Parts that were not perfect but were everywhere.

This was the invisible war. The war that never made headlines. The war fought not with bullets, but with supply chains, training manuals, and standardized tolerances. By the time German commanders realized what they were facing, the mathematics had already turned against them. Every German loss was permanent.

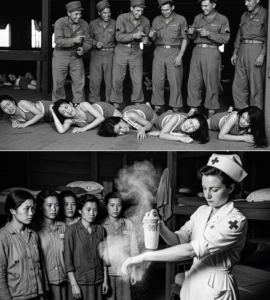

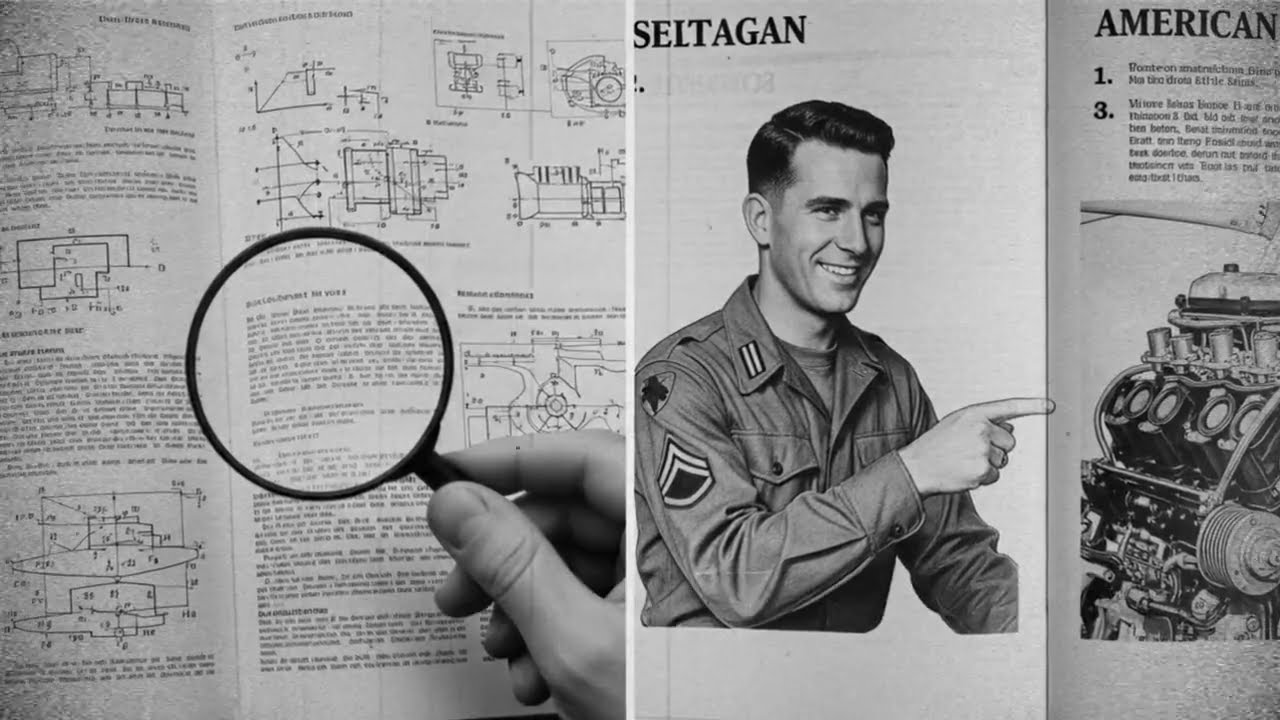

Every American loss was temporary. And that difference would decide everything. What do you think? How did the Americans build a system that made perfection irrelevant? Tell me in the comments. The first sign came not from a battlefield, but from a document, a captured American field repair manual.

It arrived at a German technical evaluation center in early 1943. The engineers who received it expected something complex, something that would reveal the secrets of American engineering. What they found instead was a series of pictures. Simple pictures, stepbystep diagrams, arrows pointing to components, numbers indicating sequence.

No mathematical formulas, no technical specifications requiring advanced training, just pictures. One engineer reportedly set the manual down and asked if this was a joke. It was not a joke. The manual was designed for soldiers with minimal education. Men who had been farmers, factory workers, store clerks just months before, men who had never seen the inside of an engine.

And yet, according to the manual, these men could replace a transmission, rebuild a carburetor, swap an entire engine block. In the field without specialist support, the German engineers stared at the pages. He did not understand. German repair manuals were textbooks, dense technical documents requiring years of training to interpret.

A German field mechanic was a skilled professional, someone who understood metallurgy, tolerances, the relationship between components. How could the Americans trust their equipment to amateurs? The answer was hidden in the margins of the manual, small notations, partnumbers, reference codes. Every component had a number.

Every number corresponded to a part that was identical to every other part with that same number. There was no variation, no tolerance ranges requiring adjustment. If part 2847B failed, you removed it. You retrieved part 2847B from supply, you installed it. Done. No measuring, no fitting, no judgment calls.

The system removed the mechanic from the equation. Not because mechanics were unnecessary, but because the system could not depend on their presence. In the chaos of war, skilled mechanics died. They were captured. They were reassigned. They were simply not where they were needed. The American system assumed this, planned for it, built around it.

The manual was not a guide for experts. It was a replacement for experts. And this horrified the German engineers because they realized what it meant. Every American soldier was a potential mechanic. Every American truck could carry its own repair capability. Every American unit was self-sufficient in ways that German units could never match.

A German Panzer division required supply lines stretching hundreds of miles. specialist parts, specialist personnel. A single broken component could immobilize an entire column. An American armored unit carried standardized parts in every support vehicle. Any crew could perform basic repairs. Mobility was maintained not through perfection, but through redundancy.

The manual contained a quality control stamp on the inside cover. Inspected, approved, ready for field use. The same stamp appeared on every replacement part referenced in the document. This was not craftsmanship. This was manufacturing. And for the first time, the German engineers felt something unfamiliar.

Doubt. They had built the finest military equipment in the world. But the Americans had built something else. They had built a system that did not need fine equipment. A system that functioned with good enough. And good enough, they were beginning to realize might be enough. One of the engineers later wrote in his personal notes about that day.

He described the manual as revealing something unsettling. He said they had spent years perfecting machines. The Americans had spent years perfecting replaceability and he was no longer certain which approach would win. If you were a German commander and you just discovered that your enemy’s weakest soldier could do what only your experts could do, what would you do? Drop your answer.

The second discovery came 3 months later. a captured American supply depot in Tunisia. What the Germans found inside changed everything. The depot contained thousands of parts, engine components, transmission gears, electrical systems, suspension elements, all organized, all labeled, all waiting. But the truly disturbing detail was not the quantity. It was the uniformity.

A German technical officer ordered a test. He selected a transmission gear at random from the shelf. He walked to a damaged American Jeep and attempted to install it. It fit. He tried the same gear on a second Jeep. It fit. A third. It fit. He then retrieved a gear from a different shelf manufactured at a different factory.

Shipped from a different location. It fit all three vehicles. The German officer stood in silence for a long moment. His aid asked what was wrong. The officer replied quietly, “These are not parts. These are copies.” He was correct. Every American factory producing the same component used identical specifications, identical tooling, identical quality control standards.

A part manufactured in Detroit was indistinguishable from a part manufactured in Chicago, Los Angeles, or Atlanta. They were not similar. They were the same. This required something the Germans had not fully appreciated. Tooling standardization. The machines that made the parts were themselves standardized, calibrated to identical specifications, maintained to identical tolerances.

A German factory producing tank components might use equipment adjusted by experienced machinists. Each factory developed its own methods, its own standards, its own interpretation of the blueprints. The result was variation, small differences that required hand fitting during final assembly. This was considered normal, even desirable.

It meant skilled craftsmen were involved at every stage. The Americans eliminated this entirely. They created master gauges, reference standards that every factory received. Every machine was calibrated against these gauges. Every part was measured against them before shipping. If a part did not match the gauge exactly, it was rejected.

No exceptions, no adjustments, no individual judgment. The captured quality control documents revealed specifications measured to thousandth of an inch. These were not guidelines. They were absolute requirements. Any deviation meant failure. This explains something else the Germans had noticed. American factories employed large numbers of unskilled workers. Women,teenagers, men too old for combat.

The Germans had assumed this was a weakness, desperation. Now they understood. The machines did the precision work. The workers simply operated the machines. Training time dropped from years to weeks. A grandmother in Michigan could produce components that met the same standards as a master machinist. Because the system did not require masters, it required compliance.

Follow the process, check the gauge, ship the part. The implications spread further than the depot. If every part was identical, then inventory became simple. One part number meant one part anywhere in the world. A supply officer in North Africa could request part 2847B and the identical component would ship from any factory with available stock.

No questions, no specifications, no confusion. The Germans tracked 16 different variants of a single fuel pump for their primary tank. Each required specific installation procedures. Each came from a different contractor. The Americans tracked one. One part number, one procedure, one solution. The captured quality control documents showed inspection rates that seemed impossible.

Thousands of parts checked per day. Statistical sampling methods that assumed defects would be rare, not common. The German officer who led the depot assessment submitted his report with a single recommendation. He suggested they study not just the parts, but the system that produced them. He wrote that the Americans had solved a problem the Germans had not recognized as a problem, the problem of scale.

German engineering was designed to produce excellence in limited quantities. American engineering was designed to produce adequacy in unlimited quantities. And in a war of attrition, adequacy multiplied by infinity would defeat excellence multiplied by scarcity every time. The report was filed.

Some officers read it. Most did not. But those who understood felt the weight of its conclusion. They were not losing to better machines. They were losing to better multiplication. Can you guess what was still missing from the American system? They had the parts. They had the factories. But one critical element remained.

The final piece was not a machine. It was not a factory. It was a training film. Captured American training materials reached German intelligence in late 1943. They expected propaganda, morale content, perhaps technical instruction for specialists. What they found was something else entirely. short films, 15 to 20 minutes each, showing ordinary soldiers performing mechanical repairs.

The soldiers in the films were not experts. Their movements were careful, uncertain. They consulted reference cards. They checked diagrams posted on the vehicles, but they completed the repairs successfully every time. The training films were not teaching mechanical engineering. They were teaching process step one, step two, step three.

Each step was simple enough that it could not be performed incorrectly. The film showed soldiers making mistakes, dropping parts, forgetting sequences. Then they showed them correcting those mistakes, using the checklist, following the process. The message was clear. You do not need to understand. You need to follow instructions. This was the missing piece.

The connection between standardized parts and field effectiveness. The parts meant nothing if soldiers could not install them. The training ensured they could. But it went further than individual mechanics. The training created redundancy in human capability. If one soldier trained on engine repair was killed, another could take his place.

Their knowledge was not specialized. It was standardized. Just like the parts, just like the factories, the Germans documented their own training programs. For comparison, a German mechanic required 18 months of technical education, apprenticeship, practical examination. An American mechanic required six weeks. The Germans trained experts.

The Americans trained replacements. And there were always more replacements. The factory redundancy was equally disturbing. American industrial intelligence revealed a system the Germans could not replicate. If a factory producing carburetors was damaged, production shifted to another facility within days, not months. The tooling was identical.

The specifications were identical. The workforce could be transferred or replaced. German factories were irreplaceable. Each one represented years of accumulated expertise, specialized equipment, trained personnel with knowledge that existed nowhere else. Destroy a German ballbearing plant and production stopped until it could be rebuilt.

Destroy an American plant and production shifted down the road. The Americans had built their industrial base like they built their equipment, replaceable, redundant, continuous. A German intelligence officer summarized it in a classified briefing. He said the Americans treat their factories like their soldiers. disposable, interchangeable, endless.

The briefing included production estimates that no one wanted to believe. American factories were producing aircraft at three times the German rate, trucks at five times, ammunition at ratios that could not be accurately calculated because the numbers changed too quickly. Every week the gap widened, not because American workers were better, but because the American system multiplied human effort in ways the German system could not match.

The training films included a detail that some analysts found particularly disturbing. Quality assurance checkpoints. After each repair, soldiers were required to verify their work against a checklist. Another soldier would confirm. A third would sign off. Three people, three checks, three opportunities to catch errors.

The process assumed mistakes would happen. It was designed to catch them anyway. German processes assumed trained professionals would not make mistakes. When they did, there was no system to catch them. So, how did the Americans achieve what the Germans could not? The answer was not brilliance. It was humility.

They designed every system assuming failure, assuming incompetence, assuming chaos. And then they built redundancy into every layer, parts that anyone could install, training that anyone could complete, factories that anyone could replace. The genius was not in the engineering. It was in the expectation of imperfection.

The war continued for two more years. Battles were fought. Territory changed hands. Headlines celebrated victories and mourned defeats. But the mathematics had already been decided. In late 1944, a German logistics officer compiled a comprehensive analysis of replacement part availability across all theater operations.

The document was never widely distributed. perhaps because its conclusions were too clear. German armored divisions were operating at 60% strength, not because of combat losses, because of maintenance failures that could not be resolved. Tanks sat immobilized, waiting for parts that would never arrive. Aircraft remained grounded for want of components that existed only in factories now under bombardment.

ships delayed in port while specialists attempted to fabricate replacements by hand. The American forces faced similar damage, similar breakdowns, similar mechanical failures, but their recovery time was measured in hours, not weeks, not months, hours. A damaged American tank returned to service before its German counterpart had even been assessed.

The numbers were relentless. For every German vehicle permanently lost to mechanical failure, the Americans lost almost none. Their losses were always temporary. Their strength was always regenerating. The German officer who had first examined the repair manual in 1943 survived the war. In his later writings, he reflected on what he had witnessed.

He wrote that they had believed engineering excellence would decide the war. They had believed that superior machines would overcome inferior numbers. They had been wrong. The Americans had not tried to build superior machines. They had built a system that made machine quality almost irrelevant. a system where every loss could be replaced, every failure could be repaired, every setback was temporary.

He wrote that they had been fighting the wrong war. They were fighting a war of quality. The Americans were fighting a war of quantity, and in a war of quantity, quality is just a disadvantage that slows production. The final German assessment of American industrial methods was completed in March 1945. It was an academic exercise by then.

The war was already lost. But the document exists in archives, a quiet admission of something the engineers had understood for years. The assessment concluded that the German approach to military production was fundamentally incompatible with modern industrial warfare. Excellence required time. Time was the one resource that war did not provide.

The Americans had understood this. Perhaps not explicitly, perhaps not philosophically, but they had built their entire system around a single assumption. Speed matters more than perfection. Availability matters more than capability. Quantity, given enough time, defeats quality. And they had been right. The German engineer who had stood in that captured supply depot holding the transmission gear that fit three different vehicles never forgot that moment.

He later described it as the moment he understood something that could not be unlearned. The Americans had not built better machines. They had built a better way of building machines. And that way was designed for exactly one thing. to keep producing no matter what. No matter how many factories were bombed, no matter how many workers were lost, no matter how many mistakes were made, the system would continue, the parts would flow, the repairs would happen, and the war would be won not by the side with the best weapons, but by the side that could replace its weapons

fastest.This is the story that rarely gets told. The story of how logistics defeated engineering, how systems defeated genius, how the boring mathematics of production defeated the brilliant poetry of design. It is not a dramatic story. There are no heroic charges, no decisive battles, no moments of individual glory.

Just a quiet realization in a supply depot on an ordinary morning. A German engineer holding an American part, understanding for the first time that the war was already over. Not because they had been outfought, but because they had been outproduced. And against a system designed for infinite replacement, no amount of excellence could ever be