-

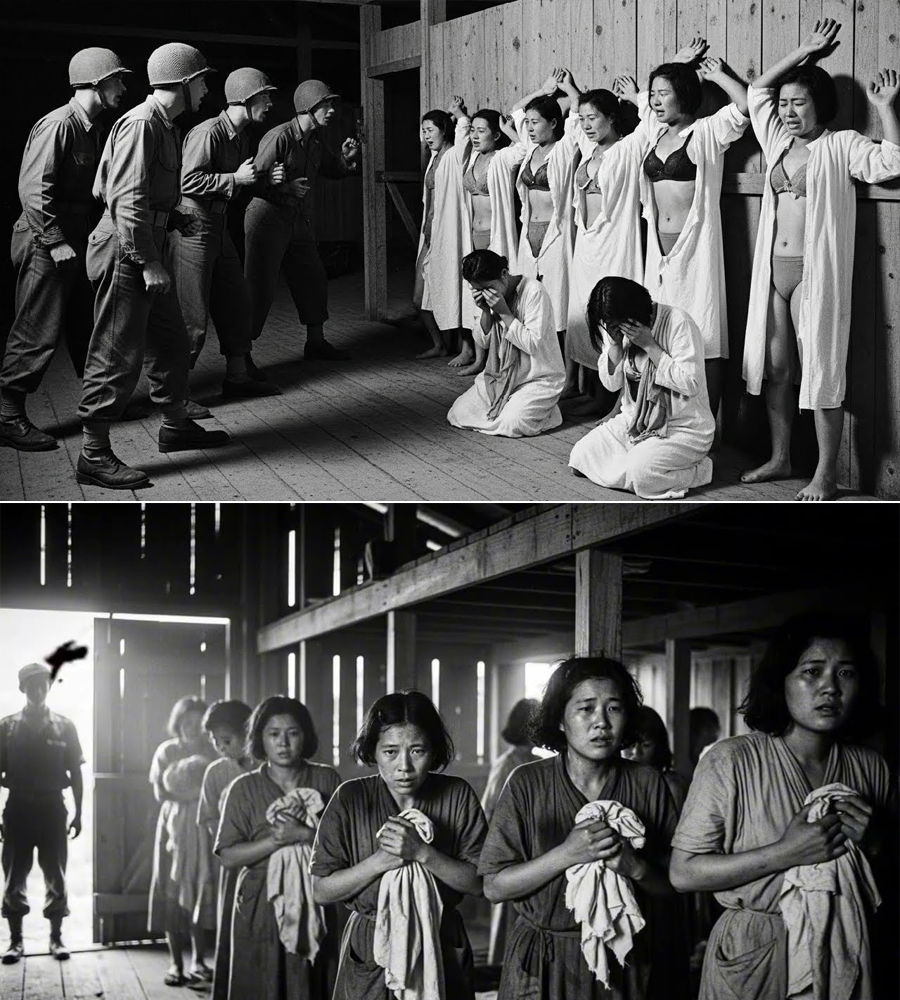

“‘On Your Knees—Polish My Boots.’ The Order That Humiliated Them… Until One Witness Broke the Silence”

“‘On Your Knees—Polish My Boots.’ The Order That Humiliated Them… Until One Witness Broke the Silence” Rain made the camp…

-

“Use Your Bare Hands—No Tools.” The Order That Broke German Women POWs, and the Quiet Revenge They Planned in the Barn

“Use Your Bare Hands—No Tools.” The Order That Broke German Women POWs, and the Quiet Revenge They Planned in the…

-

“‘Lick Your Fingers Clean After the Meal’: The Mess Hall Order That Humiliated the Prisoners—and Sparked a Quiet Revolt”

“‘Lick Your Fingers Clean After the Meal’: The Mess Hall Order That Humiliated the Prisoners—and Sparked a Quiet Revolt” The…

-

“Wash the Whole Truth Away” — The Bathhouse Order Meant to Break Them… Until One Prisoner Turned It Into a Weapon

“Wash the Whole Truth Away” — The Bathhouse Order Meant to Break Them… Until One Prisoner Turned It Into a…

-

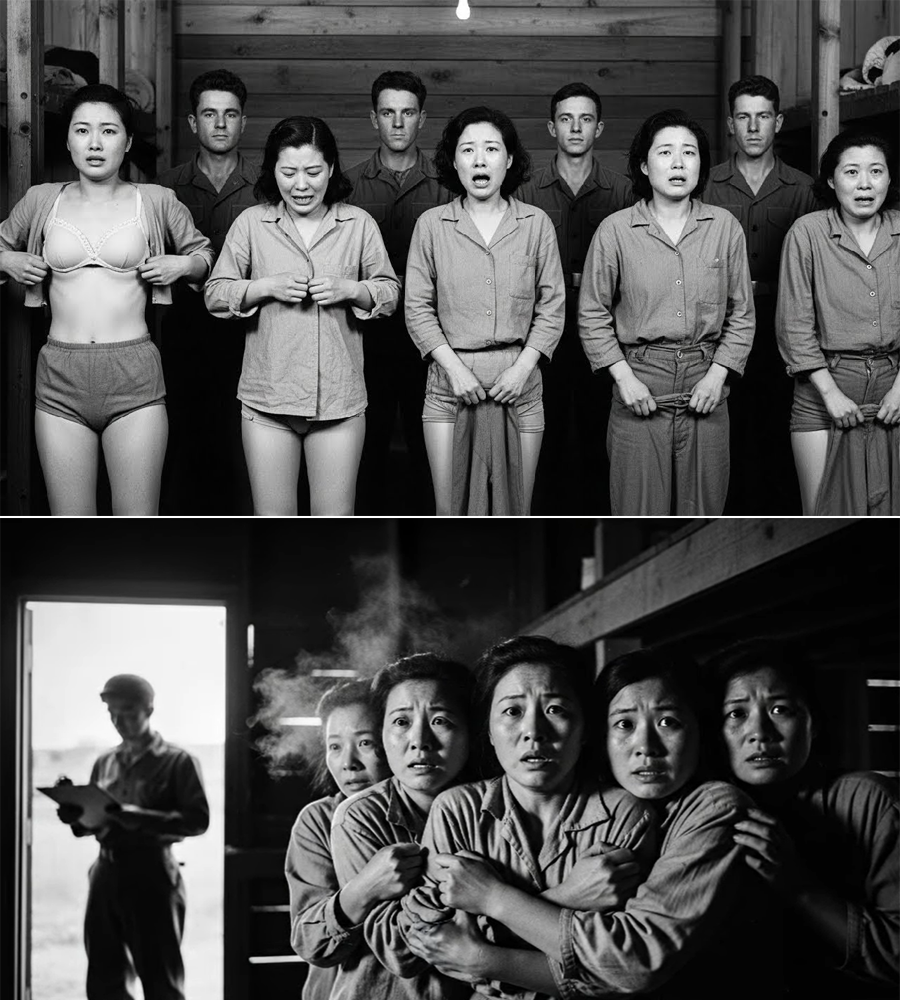

“Arms Up. Don’t Move.” The Inspection That Turned a POW Barrack Into a Silent Panic—and Exposed a Different Kind of Weapon

“Arms Up. Don’t Move.” The Inspection That Turned a POW Barrack Into a Silent Panic—and Exposed a Different Kind of…

-

“Sleep on the Floor—No Questions.” The Japanese Women POWs Thought It Was Cruelty… Until the Guards Quietly Moved Them Away From the Barracks Door

“Sleep on the Floor—No Questions.” The Japanese Women POWs Thought It Was Cruelty… Until the Guards Quietly Moved Them Away…

-

“‘Hold My Belt While I Adjust My Uniform’—Then the Women in the POW Line Saw What the Camp Was Really Hiding”

“‘Hold My Belt While I Adjust My Uniform’—Then the Women in the POW Line Saw What the Camp Was Really…

-

“Say It Again and the Walls Will Remember”—The Order Japanese Women POWs Heard, and the Reckoning That Finally Followed

“Say It Again and the Walls Will Remember”—The Order Japanese Women POWs Heard, and the Reckoning That Finally Followed The…

-

“‘Let Me Dry You After the Shower’: The POW Camp Whisper That Sparked a Riot—and a Reckoning”

“‘Let Me Dry You After the Shower’: The POW Camp Whisper That Sparked a Riot—and a Reckoning” The first rule…

-

“Layer by Layer” — The Daily Inspection Ritual That Broke Prisoners… Until One Woman Learned How to Break It Back

“Layer by Layer” — The Daily Inspection Ritual That Broke Prisoners… Until One Woman Learned How to Break It Back…